|

•Fully Automated Laser Cutting (Lights Out Manufacturing) with Full Automated Inventory Tower, Material Handler, Finished Goods Carts, etc. |

|

|

|

|

|

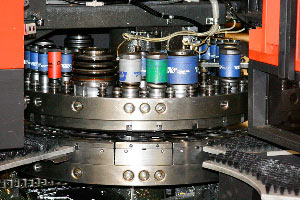

•High Speed Turret Punching of Material up to 8 feet without repositioning. •Wide Variety of Tooling including all standard tools (Rounds, Squares, Obrounds, Rectangles, Etc.) and many custom special tools (Lances, Louvers, Card Guides, Countersinks, Extrusions, etc.). |

|

|

•Auto-Tapping Head w/ Built-In Reservoir. |

|

|

•Automated Tool Grinding. | |

|

•Rolling of Material up to 6 Feet by 10 Gauge on Large Roller. •Numerous Smaller Rollers available for other applications. |

|

|

•High Quality Tig Welding of All Materials, Mig Welding, and Spot Welding of up to 1/8” Aluminum. •Extensive shop experience in fixturing while maintaining tight tolerance stackups. |

|

|

•Auto Fed Hardware Insertion with vast library of Pre-Programmed Hardware. •Wide Selection of Tooling, including a plethora of tooling for the Auto-Feed System. •Part Marking kits to enable custom text imprints on parts. •Automatic Riveting equipment including many standard rivets and custom rivets (Briv, etc.). |

|

|

•10 Foot Bending of a Variety of Gauge Material. •Ample selection of tooling including a large variety of custom tooling. •Ability to build custom tooling in house. |

|

|

•Automatic Grain Sanding, Belt Sanding, Tumbling & Vibrating, etc. |

|

|

•In-House Machining. | |

|

•Powder & Liquid Coatings. | |

|

•Silk Screening | |

|

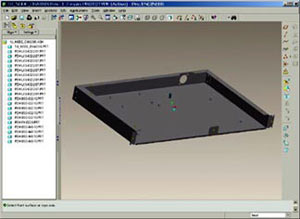

•CAD: Numerous seats (with current maintenance) on most commonly used CAD Software Packages including the most recent versions of SolidWorks, Pro-Engineer, and more. Ability to work with almost all formats of files including AutoCAD, Inventor, Visio, etc. (.DXF, .DWG, .DWF, .PRT, IGES, STEP, .PDF, and dozens more). •CAM: Numerous seats (with current maintenance) on many CAM software packages supported by extremely advanced nesting software (to minimize setups and material usage). •Extremely skilled Engineers with current proficiency on all of the above skills, along with proper documentation control, specifications callouts, current standards (ISO, RoHS Compliance, Government, Company Specific, etc.), and much more. |

|

|

||